- 15+ Years in Sportswear

Consistent production experience for long-term partners

Consistent production experience for long-term partners

Full control over quality and production schedules

Familiar with international standards and requirements

Flexible solutions for brands at different growth stages

We have focused on sportswear manufacturing for over 15+ years, working across performance activewear and gym wear categories.

Our experience covers fabric selection, fit development, and production execution for overseas markets.

Our dedicated production facility supports stable bulk manufacturing with controlled workflows.

This enables consistent quality and predictable lead times throughout the production cycle.

We work with sportswear brands across the US, Europe, and Australia.

Our team is familiar with international standards, sizing systems, and overseas communication processes.

Our production capacity is planned by product category to ensure stable output and quality control.

This allows us to handle repeat orders and scaling volumes without disrupting ongoing production.

80000 pcs / month

70000 pcs / month

50000 pcs / month

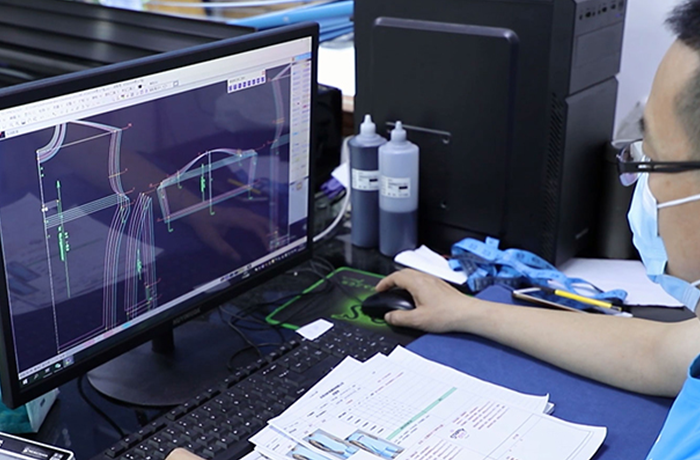

Our facility is equipped with dedicated cutting, sewing, and finishing lines designed for sportswear production.

Specialized machines support stretch fabrics, reinforced seams, and performance garment construction.

Automatic cutting, improving accuracy and efficiency

supports DTG, full-width printing

Suitable for delicate operations of complex processes.

Improves logistics efficiency.

Bulk orders are managed through structured workflows and dedicated production scheduling.

Clear process control helps maintain consistency across size sets, colors, and repeated styles.

During peak seasons, production capacity is allocated in advance based on confirmed orders and timelines.

This approach helps reduce delays and ensures stable delivery even during high-demand periods.

Sampling timelines are planned based on design complexity and fabric availability.

Clear feedback rounds and version control help reduce unnecessary revisions and keep development on schedule.

Bulk production timelines are confirmed after sample approval and material readiness.

Production schedules are aligned across cutting, sewing, and finishing to avoid bottlenecks.

Each production stage follows a defined timeline with internal checkpoints.

In-line inspections and progress tracking help ensure issues are identified early, not at the final stage.

First, we conduct an appearance inspection to ensure that the overall appearance of the clothes is flawless, including no stains, no damage, no misalignment, etc.

Next, we measure the size to ensure that the clothing size is consistent with the design requirements, including length, width, sleeve length, etc.

Thread cutting is an important step in finished product inspection to ensure that the clothes look neat. This step includes cutting off any excess threads that may exist, eliminating protruding or loose threads, and improving the overall quality and aesthetics of the clothes.

We check the sewing quality, including whether the stitches are even, whether the sewing is firm, whether the thread ends are well processed, etc.

For clothes with accessories, we check the quality and installation of the accessories to ensure that they are not missing or damaged.

Finally, we conduct detailed inspection, including whether the buttons are firm, whether the zippers are smooth, etc., to ensure that every detail meets quality standards.

ohsurewear provides custom design and pattern development to help you create unique legging styles, functional details, and brand-specific fits that stand out in the market.

Our English-speaking team ensures clear communication, detailed confirmations, and smooth coordination from sampling to bulk production.

With efficient production planning and in-house control, ohsurewear delivers fast sampling and reliable lead times with flexible scheduling.

We offer flexible MOQs, making it easier to launch new collections, test designs, and scale production without heavy upfront risk.

We supply a wide selection of sustainable and performance fabrics, including recycled and high-stretch materials tailored to your product needs.

We provide one-stop branding support, including logos, labels, hangtags, and packaging, so you can focus on growing your brand.

Our standard MOQ starts at 100 pieces per color and style, allowing brands to launch and test new products with controlled risk.

Production planning supports both initial orders and growing volumes, ensuring consistency as order quantities increase.

Multiple styles, colors, and size ranges can be produced within the same order to support collection development.

We work with brands through different growth stages, prioritizing stable production and clear communication.

Our mission is to integrate sportswear with environmental protection. We are deeply aware of the negative impact that the manufacturing industry and waste have on the environment. That’s why we strongly advocate for sustainable recycled fabrics and other eco-friendly materials. By implementing effective waste management strategies, recycling, and reducing waste, we aim to minimize the negative environmental impact.

Partner with Ohsurewear, a trusted sportswear manufacturer, and bring your custom activewear ideas to life. Fill out the form below to get a fast, detailed quote and expert guidance.